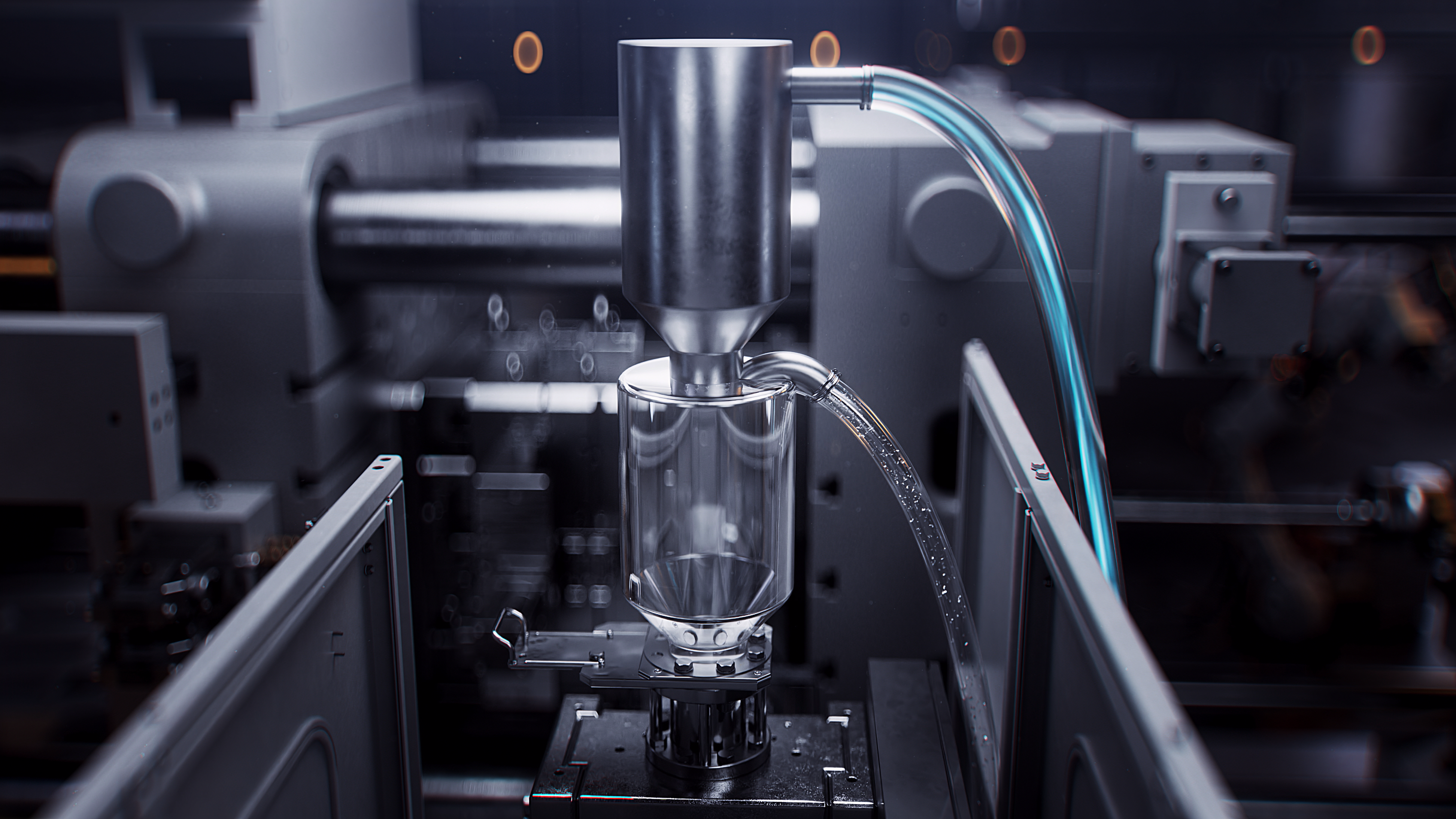

Ideal for small to medium sized products like display housings, head up displays, electronic boxes, notebook housings, e-bike motors, battery housings and many more.

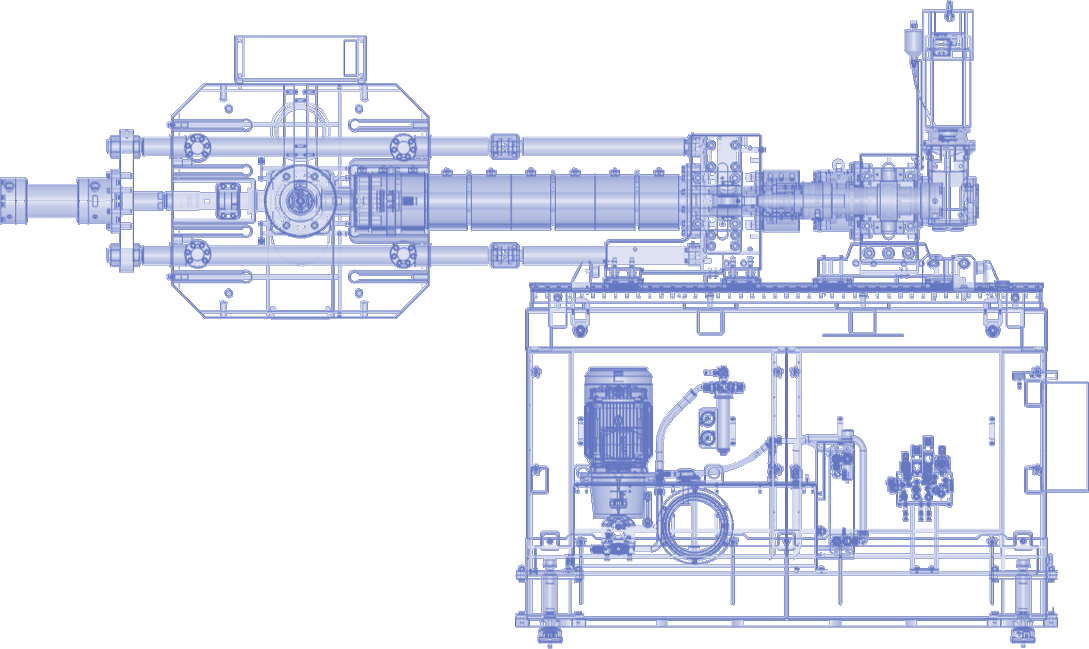

singleScrew

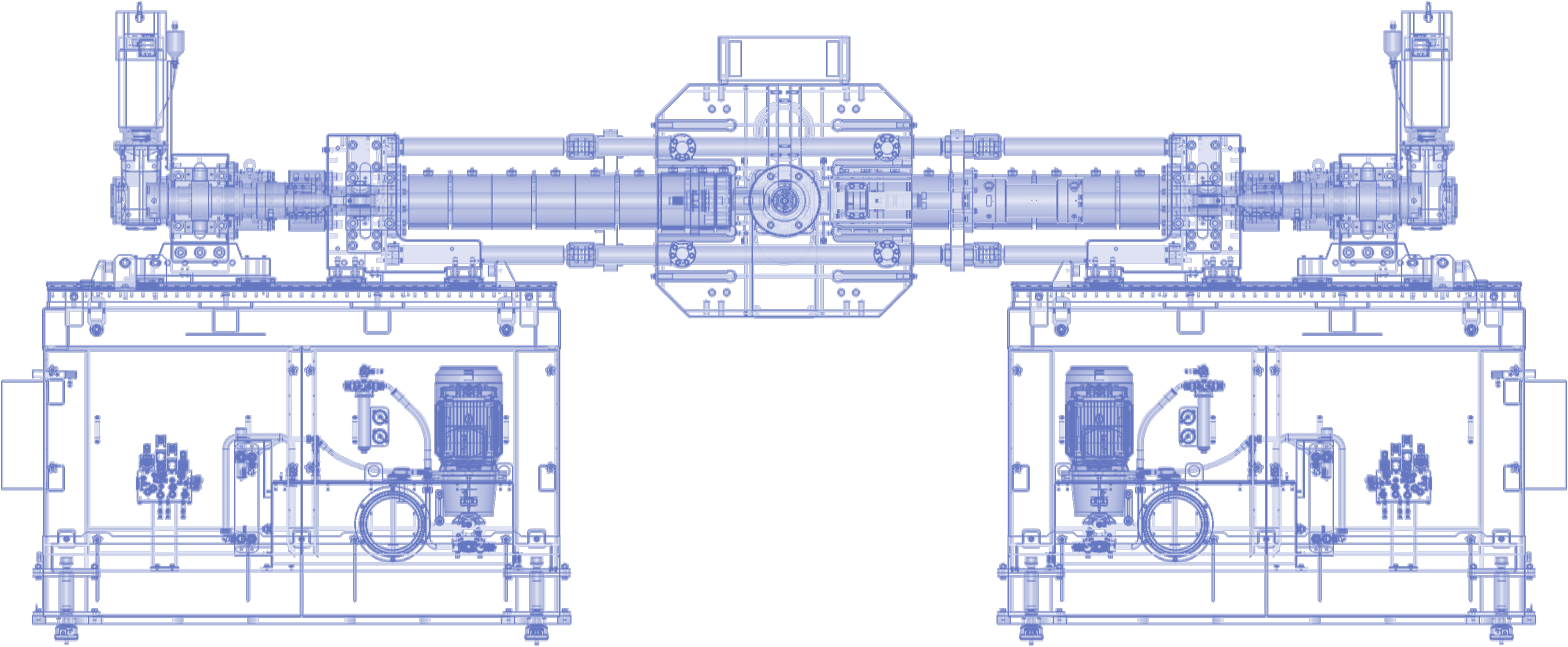

dualScrew

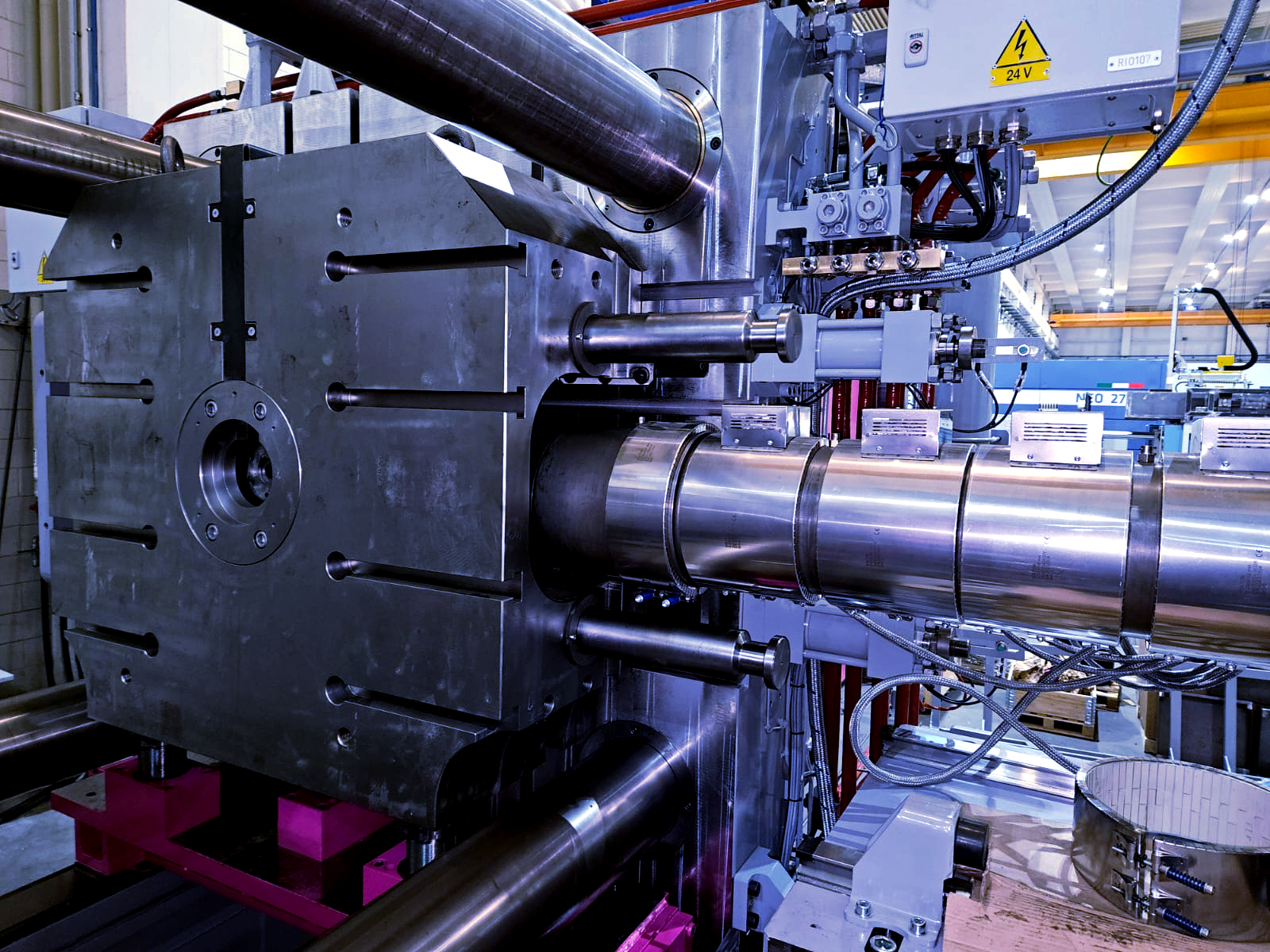

TPI Functionality

The TPI module kneads and shears the alloy with a screw, as in Thixomolding, and thus brings it to a thixotropic state. The injection feature of Thixomolding to directly inject the melt into the component cavity via a nozzle will also be retained. However, in contrast to Thixomolding no check valve is used, as in conventional die casting. This check valve is the biggest disadvantage of the Thixomolding technology. If it does not work properly, it results in various forms of process instability. In die casting, on the other hand, where only fully liquid melts can be processed, the overall process is very stable and reproducible due to its simplicity. For this reason, as in die casting, a piston will be used in our machine to move the melt.